Using FEA to Assess Structural Stability During Tower Repairs

Finite element analysis (FEA) is a useful tool to provide evaluation of the stability of towers as they undergo significant repairs and subsequent postweld heat treatment (PWHT). When performing these FEA studies, it is imperative to understand that this is not a simple run FEA and evaluate. More than anything else, these repairs require the thoughtful evaluation of multiple persons who have deep hands- on experience. SMPES, LLC principal engineer has performed these engineering repair evaluations as a Sr. Plant Engineer/Sr. Metallurgist in numerous turnaround and emergency situations, as well as an Authorized Inspector (AI) and now as a consultant for almost 20-years. Many recommendations offered for these evaluations are made from historical experiences. FEA simply provides a tool to allow detailed evaluation of stability, as well as determination of local strain levels in the soak and gradients zones.

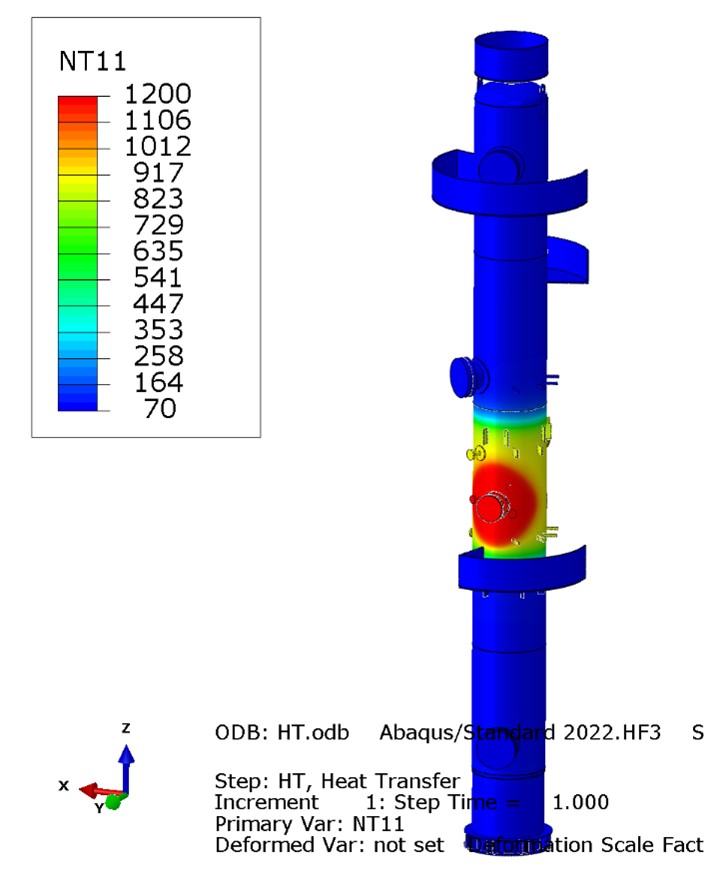

These calculated are highly regimented and are successfully used in PWHT and other weld repair activities (large cutouts of shells or skirts to replace plate material). As needed, crane loading or mechanical (beam) supports can be added and evaluated, or the PWHT temperature lowered to find a suitable temperature where the vessel material retains enough strength to withstand the dead-weight and wind load applied to it. There are numerous layers of safety factors included in these studies, from the 2.4 Code partial safety factors to the use of 1000-hr creep strengths, to treating the material as elastic-perfectly-plastic. Additionally, Nuclear Code III.5 plastic strain limits are used to make sure either the soak zone is not too small, or if the gradient zone crosses a platform (or other) clip fillet weld. As needed, this plastic strain limit is reduced when environmental factors such as hydrogen service is the equipment service.