Using Finite Element Analysis to Identify Issues in High-Temperature Chemical Reactors

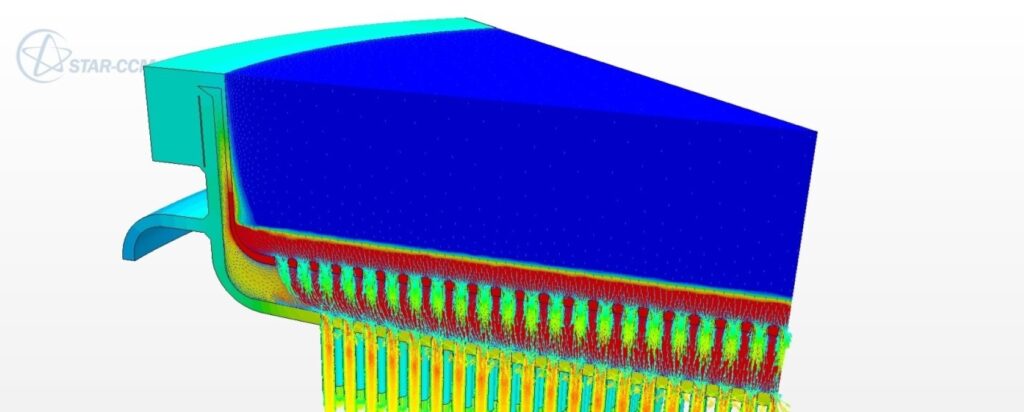

A niche for SMPES, LLC is the troubleshooting and redesign of chemical reactors. All too often high temperature chemical reactors are design straight out of ASME Section VIII Div. 1 without concern for low cycle fatigue. This is double trouble because 1) Div. 1 tends to over design components, making them thicker and more rigid, and thus, less flexible, and 2) no upfront design effort is made to determine if this rigidity is a problem with regards to a low cycle environment. The first step for troubleshooting is to identify the crack, or other deficiency, location and replicate it with a detailed FEA model. Often times this requires the use of CFD to establish true transient and/or steady-state conditions inside the reactor. Other times, the use of the more simple heat transfer convection coefficients is appropriate.

Plastic strains are evaluated in the FEA model using ASME Section VIII Div. 2 Elastic-Plastic Stress Analysis and Equivalent Strains. For evaluation of filleted weld joints, or partial-pen joints, the FEA model is re-run using linear-elastic materials. This then allows for the creation of weld submodels for evaluation per Div. 2’s Fatigue of Assessment of Welds – Elastic Analysis and Structural Stress (ESS). To accomplish this ESS evaluation, the nodal forces at the weld line are transferred from the FEA program Abaqus to FE-Safe where the weld calculations are performed per the Verity add-on software. Once the problem area has been replicated with FEA, then the redesign and re-analysis process can begin. This approach has worked over and over again for SMPES, LLC’s clients, with many successful designs now in service.