Assessing Pressure Limits to Prevent Damage in High-Temperature Reactors

At times, particularly for older (mid-1960s) low pressure, high-temperature chemical reactors, there is uncertainty with its allowable pressure ratings, particularly on the grating used to support the catalyst beds. Over the life of the reactor pressure spikes occur that cause damage to the reactor, either through uplift of the floor plate, cracking of the grating, or bulging of other areas. This fitness-for-study studied both the reactor as a whole and the grating inside.

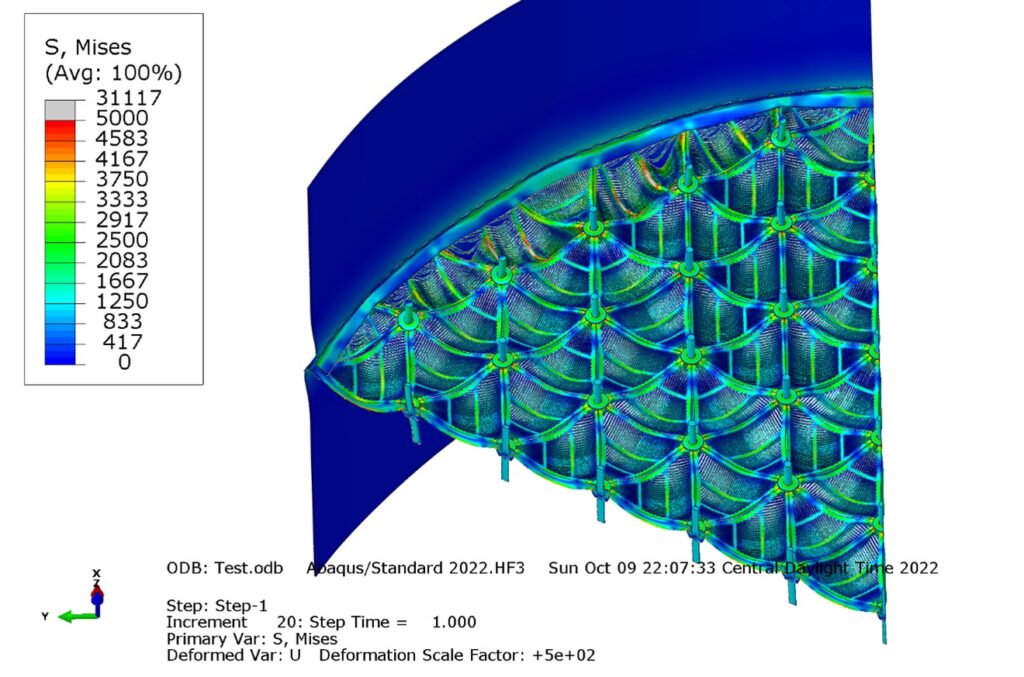

Detailed finite element analysis (FEA) models were created, especially for the grating, to allow for establishment of this maximum allowable pressure rating and maximum allowable bed differential pressure rating. Internal pressures can be plotted against expected up-lift of the floor plate. Numerous FEA analysis techniques are pursued, including non-linear FEA methods Elastic Plastic Analysis, Limit Load Analysis, and Elastic-Plastic low cycle fatigue analysis. For the fillet welds, the ASME Code recommended linear elastic Equivalent Structural Stress (ESS) method is used, taking the output of the Abaqus FEA results and feeding into FE-Safe/Verity. Previous mechanical damages to this reactor were evaluated and used as calibration/validation of the FEA model and results. In the end, the plant was provided with a clear indication of what the pressure limitations are and what would be the likely consequences of exceeding those pressures.