3D Modeling and Analysis to Resolve Excessive Vibration and Prevent Structural Failure

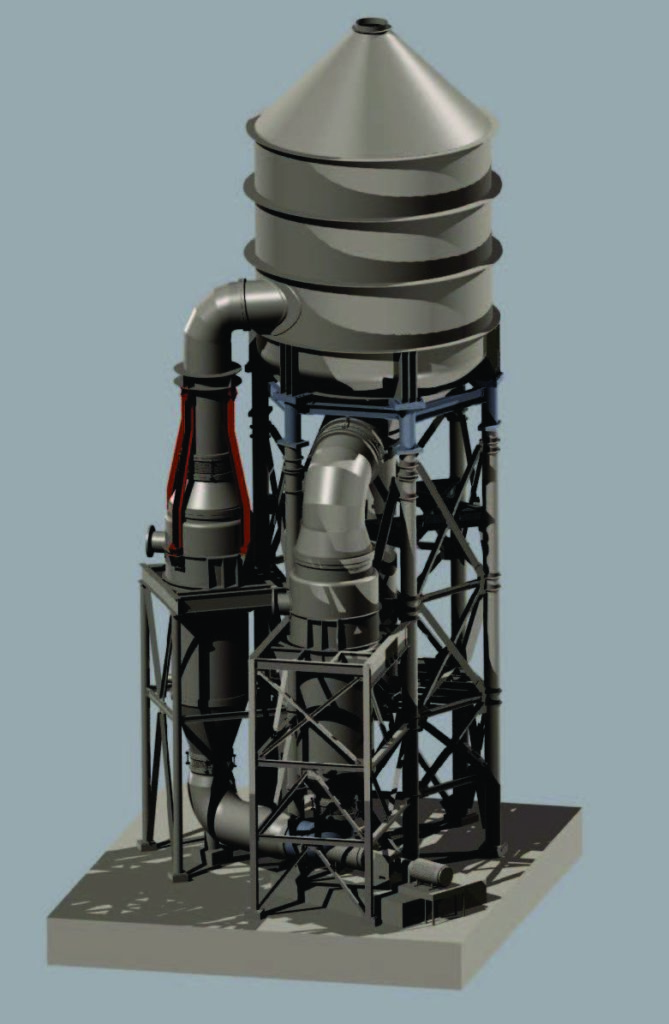

Modifications were made to both the vessel and supporting structure in a caustic unit. The consequences of making these changes without a suitable vibration study were made clear where upon startup, vibration levels were so high that structure bolting began to break. Being called upon to find the cause and more so the solution to this problem was a bit frightening. Standing at the base of the structure and watching this tall and small cross-section structure sway several inches was quite concerning to say the least. The unit was shut down and an engineering study began, first by creating a fully detailed 3D model (and subsequent FEA model) of the vessel and its structure, inclusive to the two heat exchangers also on this structure. Field vibration testing had been initially performed and this data was used to compare to the results of natural frequency studies from the FEA model. The main sway of the structure matched the lowest natural frequency for the weighted structure. Two additional vibration peaks were observed, with the worst matching the main horizontal beams the caustic vessel was bolted. Strategic structural reinforcement was added, and the main horizontal beams replaced with more stout beams. The FEA was then re-evaluated for deflection. With the FEA results showing significantly less displacement, the structural changes were made in the field. The level of vibration reduction was quite amazing, matching that predicted by the FEA model. The results were so impressive that the client then requested analysis and improvement of two additional nearby structures.